If you purchase through our partner links, we get paid for the referral at no additional cost to you! For more information, visit my disclosure page.

Ever found yourself lost in the maze of types of order fulfillment? Well, you’re not alone. But guess what? Today’s your lucky day. Why? Because I’m about to unravel the mystery for you.

And trust me, by the end of this guide, you’ll be navigating the world of fulfillment like a pro. If you’re curious about my top picks, check out my list of the best fulfillment services.

So, buckle up, and let’s dive in. And hey, maybe there’ll be a chuckle or two along the way. ????

What Are the Best Types of Order Fulfillment Services?

In the vast ocean of order fulfillment, there are a few shining stars that stand out. These aren’t just any regular fulfillment processes; they’re the ones that top businesses swear by.

Whether you’re a newbie or a seasoned pro, understanding these services is crucial to meet those ever-soaring customer expectations.

Now, you might be wondering, “Why should I trust this guide?” Well, for starters, I’ve spent a decade diving deep into the world of digital marketing and fulfillment.

And if you’re keen on learning more about one of the best services out there, I’ve got a detailed review on DSers fulfillment service that you might find handy.

Let’s take a look at the types of order fulfillment. Shall we?

Types of Order Fulfillment at a Glance

- In-House Fulfillment: Manage everything in-house, from storage to shipping.

- Third-Party Fulfillment (3PL): Outsource storage and shipping tasks to another company.

- Dropshipping: Supplier sends the product directly to your customer, no stock holding.

- Cross-Docking: Products are immediately transferred from inbound to outbound trucks, minimizing storage time.

- Just-In-Time (JIT) Fulfillment: Produce or order products only when there’s a demand, reducing storage.

- Direct-to-Consumer (DTC) Fulfillment: Brands sell directly to their end customers, bypassing middlemen.

Get a deeper dive into each type below!

1. In-House Order Fulfillment

Definition and Overview

In-house fulfillment is like cooking at home. Instead of ordering out, you handle everything yourself. In the business realm, this means managing orders, inventory, packing, and shipping all within your company. It’s the DIY approach to the order fulfillment process.

What’s Needed for In-House Fulfillment?

To run an efficient in-house fulfillment operation, there are several key components you’ll need:

- Space: A dedicated warehouse or storage area is crucial. This is where you’ll store your inventory, pack orders, and manage shipments.

- Packaging Supplies: Boxes, bubble wrap, tape, and labels are just the start. Depending on your products, you might also need specialized packaging.

- Employees: A team to manage inventory, pack orders, handle customer service, and oversee the shipping process.

- Equipment: This can range from simple shelving units to more advanced machinery like forklifts or conveyor belts.

- Inventory Management System: A software solution to track products, manage stock levels, and ensure timely order processing.

- Shipping Partners: Collaborations with courier or postal services to ensure your products reach their destinations.

Situations Where In-House Fulfillment is Ideal

In-house fulfillment shines in specific scenarios. If you’re a startup or a small business with limited order volumes, this method can be a game-changer.

It’s also perfect for businesses with unique products that require special handling or personalized touches. Think of it as making a handcrafted pizza, where every detail matters.

Pros and Cons of Managing Fulfillment Internally

Pros

Cons

2. Third-Party Fulfillment (3PL)

What is a 3PL and How Does it Work?

Third-Party Fulfillment, often referred to as 3PL, is like hiring a personal chef instead of cooking yourself. A 3PL provider takes care of all the nitty-gritty details of the order fulfillment process for you.

They store your products, pack orders, and handle shipping, all while you focus on growing your business.

What’s Needed to Run 3PL?

To effectively utilize a 3PL provider, businesses need:

- Integration: A system to integrate your e-commerce platform with the 3PL’s software for seamless order processing.

- Inventory: A consistent supply of your products to the 3PL’s warehouse.

- Communication: Regular communication channels to discuss stock levels, returns, or any special requirements.

- Agreements: Clear contracts detailing responsibilities, costs, and any other specifics.

Situations Where 3PL is Ideal

Opting for a 3PL is perfect when:

- Rapid Growth: Your business is expanding faster than you can handle order volumes.

- Global Reach: You’re looking to ship products internationally and need expertise in global logistics.

- Focus on Core: You want to concentrate on product development, marketing, and other core business areas, leaving the logistics to experts.

Factors to Consider When Choosing a 3PL Provider

Choosing a 3PL is like picking the right restaurant. You want quality, reliability, and a good fit for your needs. Here are some things to consider:

- Reputation: Check reviews and testimonials. A good track record is essential.

- Technology: Do they use modern fulfillment software and tracking systems?

- Flexibility: Can they adapt to your specific needs and preferences?

- Cost: While you want affordability, the cheapest option isn’t always the best.

Pros and Cons of Outsourcing Fulfillment to a Third Party

Pros

Cons

3. Dropshipping Order Fulfillment

Definition and Overview of the Dropshipping Model

Dropshipping is the business equivalent of ordering takeout. Instead of stocking products yourself, you partner with suppliers who ship products directly to your customers.

When an order comes in, you simply forward it to your supplier, and they handle the rest. While the most popular method involves using Chinese suppliers, dropshipping is essentially any model where a supplier sends products directly to your customer without you holding stock.

This can be local suppliers from your city, US suppliers, AU suppliers, or any other suppliers from around the globe using DSers. It’s the ultimate hands-off approach to the order fulfillment process.

What’s Needed to Run Dropshipping?

To effectively run a dropshipping model, businesses need:

- Supplier Relationships: Reliable partnerships with suppliers who offer dropshipping services.

- E-commerce Platform: A platform that supports dropshipping integrations, allowing for seamless order forwarding.

- Quality Control: Even though you don’t handle the products, ensuring product quality is crucial for customer satisfaction.

- Clear Communication: Regular touchpoints with suppliers to discuss stock availability, product updates, and shipping times.

Differences Between Dropshipping and Traditional Fulfillment

While traditional fulfillment involves stocking and shipping products yourself, dropshipping eliminates these steps. Instead, your supplier handles inventory and shipping. This means:

- Less Capital Needed: No need to buy inventory upfront.

- Flexible Product Range: Easily test and change products without financial risk.

- Reduced Overheads: No warehousing or shipping costs on your end.

Situations Where Dropshipping is Ideal

Dropshipping shines when:

- Startup Phase: When you’re just starting out and have limited capital.

- Testing New Products: Introduce new items without the risk of unsold stock.

- Limited Storage: If you don’t have space for inventory, dropshipping is a no-brainer.

Pros and Cons of Dropshipping

Pros

Cons

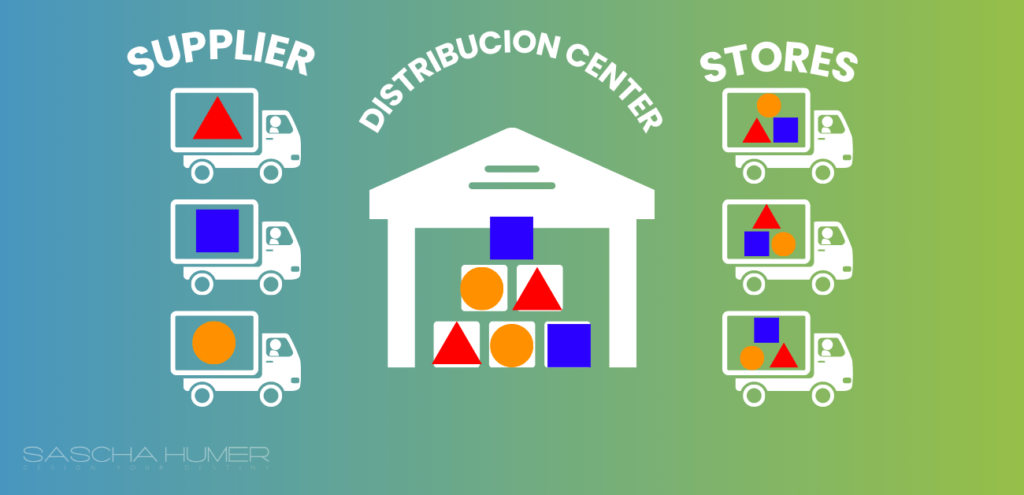

4. Cross-Docking

Explanation of the Cross-Docking Process

Imagine you’ve ordered a fresh pizza for a party. Instead of the pizza place baking it hours in advance and letting it sit, they prepare it just in time for the delivery driver.

The moment it’s out of the oven, the driver grabs it and heads straight to your door. That’s cross-docking in the logistics world.

Products arrive at a docking terminal, and instead of being stored, they’re immediately transferred to outbound trucks for delivery.

It’s about minimizing storage and ensuring products are as fresh and timely as that pizza.

Ideal Scenarios for Using Cross-Docking

Cross-docking is a star performer when:

- Perishable Goods: Items like fresh produce or dairy products that need to reach customers quickly.

- High Turnover Items: Products that sell out fast and don’t require long-term storage.

- Pre-Packaged Products: Items ready for sale and don’t need additional handling or packaging.

Pros and Cons of Reducing Storage Time and Costs

Pros

Cons

5. Just-In-Time (JIT) Fulfillment

Overview of the JIT Model

Think of JIT Fulfillment as the Netflix of the logistics world. Just as you stream a movie when you want to watch it, rather than storing DVDs at home, JIT ensures products are produced or ordered only when there’s a demand.

It’s somewhat similar to Print on Demand (PoD). While PoD specifically involves creating products (like t-shirts or books) once an order is placed, JIT applies this on-demand principle more broadly across various industries, ensuring timely delivery without excess stock.

Situations Where JIT is Ideal

JIT is most effective when:

- Predictable Demand: For products with stable and predictable demand, ensuring you won’t face sudden stockouts.

- High Storage Costs: If warehousing costs are high, JIT can reduce the need for long-term storage.

- Perishable Goods: Items that have a short shelf life and need to be sold quickly, like fresh produce or seasonal items.

Pros and Cons of Just-In-Time

Pros

Cons

6. Direct-to-Consumer (DTC) Fulfillment

Explanation of DTC and its Rise in Popularity

Direct-to-Consumer (DTC) Fulfillment is akin to a local coffee roaster selling their unique blends directly on their website, bypassing supermarkets or coffee chains.

In the broader business landscape, DTC means brands sell directly to their end customers without third-party retailers, wholesalers, or other intermediaries.

This approach has seen a surge, especially with the rise of e-commerce platforms and social media marketing, allowing brands like our coffee roaster to reach a global audience with their special brews.

Situations Where DTC is Ideal

DTC shines brightest when:

- Unique Products: If you have a niche or specialized product, like artisanal cheeses or handcrafted jewelry, direct selling can help maintain its uniqueness.

- Brand Narrative: For brands with a compelling story or mission, DTC allows for a direct storytelling platform.

- Direct Feedback Loop: Brands looking for immediate feedback to iterate and improve their products benefit from the direct customer relationship.

Pros and Cons of Selling Directly to Consumers

Pros

Cons

How Can Fulfillment Services Benefit You?

Choosing the right fulfillment service is like picking the perfect workout routine. It has to fit your goals, capabilities, and resources. When aligned correctly, the benefits can be game-changing:

- Scalability: As your business grows, certain fulfillment methods can easily adapt, ensuring you’re not left struggling with sudden demand spikes.

- Cost Efficiency: Picking the right service can lead to significant savings, especially when it comes to storage and shipping costs.

- Customer Satisfaction: Faster deliveries, accurate orders, and fewer mistakes lead to happier customers. And we all know a happy customer is a returning customer!

- Flexibility: Some methods offer more flexibility in terms of storage, handling, and shipping, allowing you to experiment and find what’s best for your products.

Buyers Guide: How We Conducted Our Research

When it comes to finding the best types of order fulfillment, we didn’t just throw darts at a board and hope for the best. We put on our detective hats and dove into the nitty-gritty. Here’s how we conducted our research:

- Pricing: We compared the costs of different services, ensuring we found options that provide value without breaking the bank.

- Features: We looked at what each service offers, from tracking capabilities to packaging options, to find the ones that truly stand out.

- Negatives: No service is perfect, so we identified potential drawbacks and challenges for a well-rounded view.

- Support or Refund: We evaluated the support and refund policies, because let’s face it, sometimes things go wrong, and you want a company that stands behind its service.

- Customer Expectations: We considered how each service meets or exceeds customer expectations, because a happy customer is the best advertisement.

- Fulfillment Strategy: We assessed how each service aligns with different business strategies, whether you’re a small startup or a booming enterprise.

- Inventory Management: We analyzed how each service handles inventory, because no one wants to be the business equivalent of a squirrel that forgot where it hid its nuts.

Wrapping Up

After diving deep into the world of types of order fulfillment, it’s clear that there’s no one-size-fits-all solution. It’s like choosing between ice cream flavors; while some might crave classic vanilla, others might be in the mood for a more exotic mango-chili fusion.

The key is to understand your business needs, customer expectations, and resources. Whether you’re a budding entrepreneur launching a passion project or a seasoned business mogul expanding your empire, the right fulfillment strategy can make all the difference.

Remember, in the ever-evolving world of e-commerce, staying informed and adaptable is crucial. So, keep an eye on emerging trends, continuously assess your fulfillment strategy, and always strive for customer satisfaction.

And hey, if you ever feel overwhelmed, just think of this as choosing an ice cream flavor. Take a moment, weigh your options, and go with what feels right. After all, in the grand scheme of things, it’s all about delivering delight, one order at a time.

Frequently Asked Questions

Navigating the maze of types of order fulfillment can spark a flurry of questions. So, we’ve scoured the internet, peeked into forums, and even consulted the oracle (okay, maybe not the oracle, but definitely Google) to address some of the most burning queries.